|

|||

|

|

|

||||||||||

|

||||||

Insist on Genuine Thermo King Replacement PartsEngineered to provide optimal performance and maximum life, Thermo King genuine service parts protect your investment and provide you peace of mind and confidence no matter where your equipment operates. Genuine Thermo King replacement parts are proven time after time to beat the competition in side-by-side testing. Never settle for less. |

Warranty SummaryThermo King Warranty are available on request from your local Thermo King Dealer. Please refer to document TK50048 for the Thermo King Container unit warranty. |

||||||

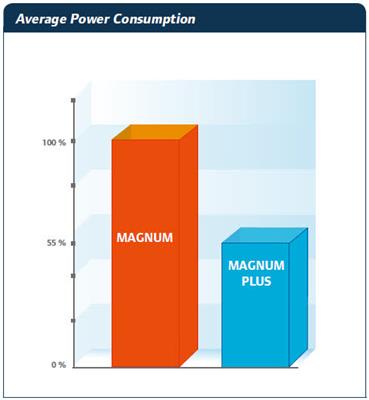

Efficiency without compromiseAs the founder of transport refrigeration, Thermo King has always been committed to engineering innovative products and technologies and providing new levels of efficiency and performance for customers across the globe.The MAGNUM PLUS™ is the result of years of field experience acquired with its predecessor the MAGNUM™. Through advanced technology and research & development Thermo King has introduced with the MAGNUM PLUS™ a new industry benchmark in efficiency, performance, operability and reliability. The MAGNUM PLUS™ is conceived to answer to the most stringent requirements. |

|

Maximum performance through efficient design |

||

Low Energy ConsumptionLess energy is required with MAGNUM PLUS™ advanced features, allowing significant cost savings and setting a new standard in efficiency |

Faster pull downThanks to its superior cooling capacity, the MAGNUM PLUS™ can increase storage life by reaching the set-point faster and more accurately. |

|

Minimising Environmental ImpactThe future is greener with MAGNUM PLUS™: thanks to its efficient operation, MAGNUM PLUS™ decreased the impact on the environment without compromising temperature control. |

Reduced WeightAdvanced design methods and the optimization of components result in the lowest unit weight on the market, thereby significantly increasing overall cargo capacity. |

|

Lowest TemperatureThe MAGNUM PLUS™ is the only unit on the market capable of reaching and maintaining -40°C box temperature in +50°C ambient environment, thereby preserving product quality and further increasing usable box life. |

Tested TechnologyWith over 100,000 units in service and with years of experience, the MAGNUM platform has been recognised by the industry as extremely reliable. |

|

Tight Temperature ControlThanks to advanced temperature management control systems, MAGNUM PLUSTM delivers extremely accurate temperature control as required in modern refrigeration. |

Global ServiceThermo King global network will provide the support you need around the Globe, around the clock. |

|

Lower Total Cost of OwnershipThe straightforward design of the system enables easy maintenance. This together with the low energy consumption ensures a low total cost of ownership. This unit not only delivers great performance, but also promises to be an ideal and profitable investment. |

||

The Mp-4000 : A big leap forward in controller technology |

||

User-friendly interfaceA high resolution VGA graphic display allows clear and efficient visualization of all data needed in every situation. Dynamic soft- and hot-keys in the navigation menus provide immediate access to key functions.Advanced communication capabilityInterfacing capabilities with advanced telematics systems make the MP-4000 the controller of choice.Standard Features• R-404A refrigerant• Scroll Compressor with Digital Control Valve for capacity modulation, economizer circuit, ambient compensated internal overload and high temperature protection • Proportional-integral differential (PID) • Refrigeration capacity control system • Non-corrosive maritime construction, which includes a marine-treated aluminum alloy frame, non-corrosive fittings, stainless steel hardware, condenser coil with epoxy e-coat and polyurethane top coat for UV protection, hydrophilic coating on evaporator coil, and a marine duty protective coating on the compressor • Condenser and evaporator fan motors, which include stainless steel shafts and internal thermal overload protection • CFC-free, foamed-in-place insulation • Wired for 380/460 volt, three-phase, 50/60 Hz power supply with an 18 meter (60 ft) 11/4 power cable with CEE-17 plug • Bottom air discharge • Automatic electronic phase correction system • 29 Vac control system • On-demand defrost combined with intelligent timed defrost • Manual defrost with initiation via MP-4000 • Indicator lights, which include Alarm, Alarm acknowledges, in range, and approaching in range • Time delay start sequence |

Simple and robust controller design:• Ruggedised box• Safety door-locking mechanism • Simplified keyboard and menu navigation system • Long-life, solid-state components with patented architecture • Reduced and simplified cabling connections • Composite condenser and evaporator fans • Conforms to ISO classifications and specifications for thermal containers, including: racking and end-loading standards, TIR specifications, ATP refrigeration standards, ARI standards for rating refrigeration capacity, UIC international Union of Railways, Australian Electrical Certification, British Standard 3755 Requirement (TAINT), USDA requirements for “Insect Cold” treatment, and Agrotechnological Research Institute (ATO-DLO) for flower bulb transportation • Auxiliary battery and charger • USDA “Cold Treatment” provision Options• AFAM+ Advanced Fresh Air Exchange Management• Water Cooler Condenser • Thermo King electronic chart recorder • Partlow temperature recorder • Saginomiya Temperature recorder • Remote monitoring • Transfresh provision • 10/4 power cable • De-humidification control |

|